Key Takeaways – How Long is a Serial Number

- Serial Number Length and Purpose: Serial numbers are essential for uniquely identifying rental equipment, ranging in length from 6 to 30+ characters depending on manufacturer and production needs. They are the foundation for tracking and managing individual items in large inventories.

- Barcode Integration: Using barcodes with serial numbers speeds up the check-in and check-out process, allowing rental companies to quickly scan and update inventory while maintaining accurate records linked to each item’s serial number.

- Enhanced Tracking with RFID: RFID tags complement serial numbers by enabling wireless scanning and real-time tracking, especially beneficial in large inventories or where quick, bulk scanning is needed without direct line-of-sight requirements.

- Efficient Inventory Management: Combining serial numbers with barcodes and RFID tags creates a comprehensive equipment management system that improves efficiency, minimizes loss, and supports ongoing maintenance and repair tracking, essential for the fast-paced rental industry.

1. What is a serial number?

Serial numbers are unique alphanumeric codes assigned by manufacturers to individual pieces of equipment. In the AV rental industry, where companies handle a large volume of expensive and technical audio visual equipment, serial numbers serve as a fundamental identification tool. Every camera, audio mixer, or projector has a serial number, allowing it to be uniquely identified and tracked throughout its lifecycle.

These numbers are not only essential for inventory tracking but are also key for warranty claims, repair histories, and theft prevention. For rental companies, maintaining detailed records of each serial number ensures that equipment is used efficiently and remains in good condition.

2. How Long is a Serial Number?

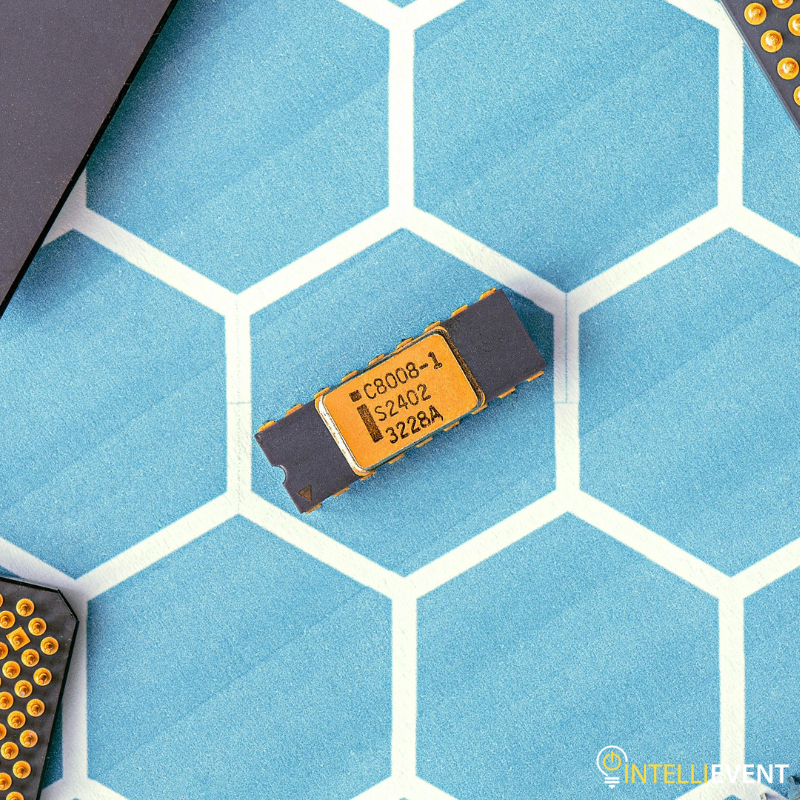

Serial numbers can vary widely in length, typically ranging from 6 to 30 characters. Beyond just length, these characters often represent specific information that can help track the item’s origin, production details, and even features. Here’s a breakdown of what different sections of a serial number might signify:

– Manufacturer Code: Some serial numbers start with a few letters or numbers that indicate the manufacturer or brand. This helps differentiate items when similar products are in use.

– Product Model or Type: Another part of the serial number might reflect the product line or model, useful for identifying the specific category of equipment (e.g., camera, projector, or speaker).

– Production Batch or Location: Serial numbers often include a code that shows the production batch or facility where the item was manufactured. This is particularly helpful for warranty or recall purposes, as it ties the item to a specific production run.

– Unique Identifier: Finally, the serial number ends with a sequence unique to that specific item, ensuring no two items share the same code. This is essential for tracking individual items within large inventories, especially in industries like AV rental, where each item’s usage, maintenance, and location need to be accurately monitored.

These combined elements within the serial number make it a powerful tool for identification and tracking across an item’s lifecycle.

3. Types of Serial Numbers: Sequential vs. Random

Serial numbers can be categorized primarily into two types based on how they are structured: sequential and random. Each type serves different purposes and offers unique benefits, especially in tracking and identifying equipment in industries like AV rentals.

Sequential Serial Numbers

Sequential serial numbers follow a numerical or alphanumeric order, where each item produced is assigned the next number in the sequence. For example, if one projector has the serial number “PROJ1001,” the next might be “PROJ1002.”

Benefits of Sequential Serial Numbers:

– Easier Tracking: Sequential numbers allow for simpler tracking and inventory management, as they follow a clear and logical order.

– Production Insight: They provide information on the order in which items were manufactured, making it easy to identify older items or pinpoint specific production batches.

– Simplified Maintenance Records: Sequential numbers make it easier to log maintenance and repairs chronologically, especially useful for AV rental companies with high equipment turnover.

Limitations of Sequential Serial Numbers:

– Predictability: Sequential numbers can be easier to guess or manipulate, which may be a concern in industries where security is paramount.

Random Serial Numbers

Random serial numbers are generated using algorithms to create a unique, non-sequential alphanumeric code for each item. For instance, one camera might have a serial number like “CAMX29Q8” and another “CAML3R7Z.” These numbers are not in any particular order, which makes them less predictable.

Benefits of Random Serial Numbers:

– Enhanced Security: Random serial numbers are harder to guess or duplicate, which can help prevent counterfeit equipment or unauthorized use of serial numbers.

– Unique Identification: By ensuring that each number is entirely unique, random serial numbers reduce the risk of duplicate or similar numbers, especially valuable for high-value equipment.

Limitations of Random Serial Numbers:

– More Complex to Track: Because there’s no logical sequence, random serial numbers can be harder to organize and track manually, which makes automated inventory systems essential for businesses that rely on them.

4. The Purpose of Serial Numbers for Rental Equipment

Serial numbers serve several critical functions in the rental industry:

– Unique Identification: Serial numbers ensure that each piece of equipment can be individually identified, which is crucial in the rental business where items are constantly being checked in and out.

– Warranty and Repair Tracking: Manufacturers and service providers use serial numbers to track warranties and repair histories, helping companies manage equipment over its lifecycle.

– Inventory Management: Serial numbers are essential for inventory systems that keep track of where each piece of equipment is at any given time. This prevents losses and ensures that equipment is available when needed.

– Theft Prevention: If equipment is lost or stolen, serial numbers can be used to identify the item if it is recovered. They are often reported to law enforcement in the case of theft.

5. Barcodes and Their Interaction with Serial Numbers

While serial numbers provide unique identification, barcodes offer a more efficient way to scan and manage large volumes of equipment. A barcode is essentially a visual representation of a serial number or another identifying code. By scanning a barcode, rental companies can quickly update their inventory systems with information about the equipment.

Barcodes can be printed on or etched into equipment labels, making it easy to scan during check-in/check-out processes. The use of barcodes in conjunction with serial numbers allows for faster, more efficient management of equipment.

For example, a high-end camera might have a barcode label attached to it, which, when scanned, pulls up the camera’s serial number in the rental company’s inventory system. This ensures that both the barcode and the serial number are linked, creating a dual system of identification.

6. RFID: Enhancing Tracking Beyond Serial Numbers

RFID (Radio Frequency Identification) technology takes equipment tracking a step further by allowing for wireless scanning of tags attached to equipment. Unlike barcodes, RFID tags do not require a direct line of sight to be scanned, which makes them ideal for environments where equipment is frequently moved or stored in bulk.

In the AV rental industry, RFID tags are often used to complement serial numbers and barcodes. RFID tags can be embedded into equipment labels, and when scanned, they provide a wealth of information, including the serial number, without the need for manual entry.

For example, an AV rental company might equip all of its projectors with RFID tags. During check-out, the RFID system reads each tag, logs the serial numbers, and updates the system without the need for visual scanning.

7. Serial Numbers, Barcodes, and RFID: A Combined Approach

The most effective equipment management systems in the rental industry use a combination of serial numbers, barcodes, and RFID tags. Here’s how they work together:

– Serial Numbers: Provide a unique identifier for each piece of equipment, offering the most basic level of identification.

– Barcodes: Allow for quick, visual scanning of serial numbers, speeding up check-in/check-out processes.

– RFID Tags: Enable wireless tracking of equipment, making it easier to manage inventory in real-time without manual scanning.

By combining these three methods, rental companies can create a comprehensive tracking system that minimizes errors, improves efficiency, and ensures that equipment is properly maintained.

8. Best Practices for Managing Serial Numbers in the Rental Industry

To maximize the effectiveness of serial numbers in equipment management, rental companies should follow these best practices:

– Consistent Labeling: Ensure that all equipment is properly labeled with a serial number that is clearly visible. This includes affixing barcodes or RFID tags where appropriate.

– Regular Inventory Audits: Perform periodic audits to ensure that serial numbers in the system match the actual equipment on hand. This helps prevent discrepancies and identifies lost or misplaced items early.

– Maintenance Tracking: Use serial numbers to track maintenance and repair histories for each piece of equipment. This ensures that equipment is serviced regularly and that any recurring issues are flagged for attention.

– Training Staff: Ensure that all staff members are trained to properly scan and track serial numbers during equipment check-in and check-out. This reduces the likelihood of errors and improves overall efficiency.

9. Technological Advances in Equipment Tracking

As technology continues to evolve, new innovations are improving the way rental companies track and manage their equipment. Cloud-based inventory systems, mobile apps, and AI-driven analytics are making it easier to manage large volumes of equipment across multiple locations.

Serial numbers remain a key component of these systems, but they are increasingly integrated with advanced tracking technologies like RFID and GPS. This allows for real-time monitoring of equipment, ensuring that every piece is accounted for, no matter where it is.

10. How to Choose the Right Identification System

Choosing the right identification system for your rental business depends on several factors, including the size of your inventory, the types of equipment you rent, and your operational needs. While serial numbers are a must-have for any business, you may also want to consider adding barcodes or RFID tags to streamline your processes.

– Small Inventories: For businesses with smaller inventories, serial numbers and barcodes may be sufficient to manage equipment effectively.

– Large Inventories: Larger businesses or those with complex inventories may benefit from adding RFID tags, which allow for more efficient, automated tracking.

11. Conclusion

Serial numbers play a vital role in the rental industry by providing unique identifiers for equipment, ensuring efficient tracking, and facilitating maintenance and repairs. Whether combined with barcodes or RFID technology, serial numbers remain the foundation of any effective equipment identification system.

By understanding how long serial numbers typically are and how they interact with other identification technologies, rental companies can implement best practices that enhance efficiency, reduce loss, and improve overall business operations.

FAQ – How Long is a Serial Number?

- How long is a typical serial number for AV equipment?

Serial numbers can range from 6 to over 30 characters in length, depending on the manufacturer and the uniqueness requirements of the equipment. Most commonly, they fall between 8 and 20 characters for AV equipment.

- Why do AV rental companies use serial numbers, barcodes, and RFID tags together?

Using these identification methods together enhances accuracy and efficiency. Serial numbers provide unique identifiers, barcodes allow for fast scanning, and RFID tags enable wireless tracking, creating a comprehensive system for managing and tracking equipment.

- What is the difference between a serial number and a barcode?

A serial number is a unique alphanumeric code assigned to a specific item by the manufacturer. A barcode, on the other hand, is a visual code that can represent the serial number, making it easier to scan quickly without manual data entry.

- How often should rental companies audit their inventory using serial numbers?

Regular inventory audits, ideally quarterly or biannually, help ensure that serial numbers in the inventory system match the physical items on hand, reducing discrepancies and preventing loss or misplacement.